SPECIFICATIONS

| Application: |

|

SAE Rating: | N/A |

|---|---|---|---|

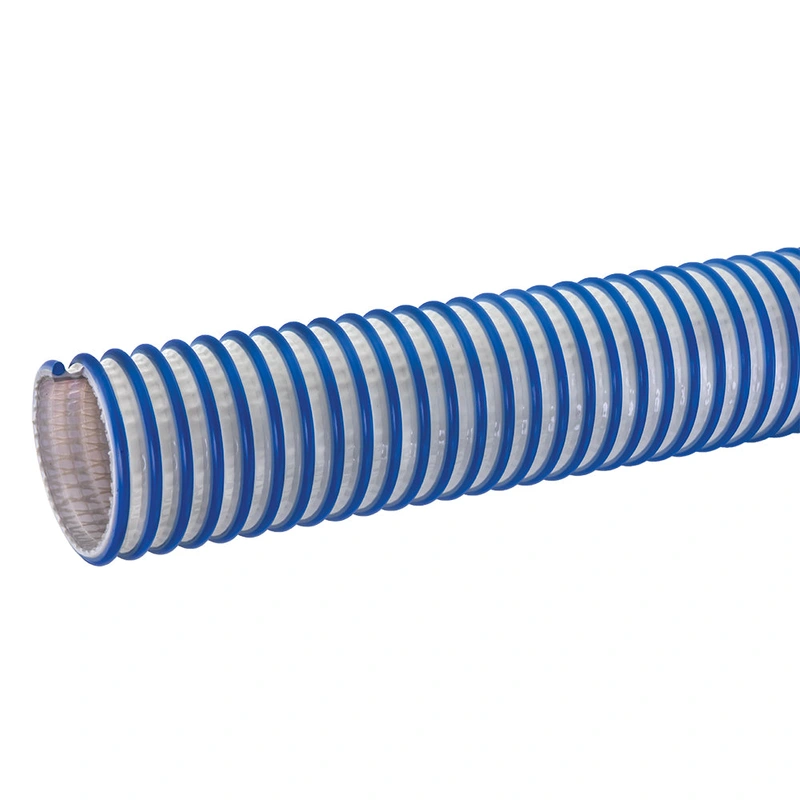

| Other Ratings: | 3A (18-03), FDA | Tube: | White nontoxic CIIR. Meets FDA and 3A (18-03) requirements. |

| Reinforcement: | High tensile textile cords with embedded PET helix. | Cover: | White EPDM – abrasion and ozone resistant. |

| Temperature Range: | -22F (-30C) to +226F (+108C) | ||

| Other Features: | |||

|

*This correction is to rectify the relationship between the unit proof and % alcohol content in the U.S. system. The alcohol content % = 0.5 x Proof. There arediscrepancies between proof and % alcohol content as it differs from country to country. Calculations for the U.S. are shown here. EXAMPLE: Proof is a method ofmeasuring the alcohol content of spirits. A spirits product that has a 40% alcohol content by volume is 80 proof [40 multiplied by 2 = 80].

| Part Number | ID | OD | Max. Recommended Working Pressure (PSI) |

Vacuum Rating (in. Hg) |

Min. Bend Radius at 68F |

Standard Length Coil |

Weight (Lbs/Ft) |

||

|---|---|---|---|---|---|---|---|---|---|

| (in.) | (mm) | (in.) | (mm) | ||||||

| T410LL100X100 | 1″ | 25mm | 1.46″ | 37mm | 240 PSI | 30in. Hg | 4″ | 100ft | 0.60 lbs |

| T410LL150X100 | 1-1/2″ | 38mm | 2.05″ | 52mm | 240 PSI | 30in. Hg | 6″ | 100ft | 1.00 lbs |

| T410LL200X100 | 2″ | 51mm | 2.56″ | 65mm | 240 PSI | 30in. Hg | 8″ | 100ft | 1.29 lbs |

| T410LL300X100 | 3″ | 76mm | 3.62″ | 92mm | 240 PSI | 30in. Hg | 12″ | 100ft | 2.23 lbs |

Reviews

There are no reviews yet.